Smart Textiles in Europe: The Next Tech Disruption – Interview with Andreas Lymberis (Part 1)

Andreas Lymberis of the European Commission

Andreas Lymberis has been a research and innovation programme officer with the European Commission (EC) in Brussels since 1999. He heads the European Innovation Council Challenge-based Accelerator sector at EISMEA (European Innovation Council and SMEs Executive Agency), having previously led Wearables and Bioelectronics initiatives for 20 years. A physicist with a Ph.D. in biomedical engineering and sciences, Andreas has robust experience as a researcher/engineer and R&D manager in biomedical technology. He is a senior member of The Institute of Electrical and Electronics Engineers (IEEE) and has published over 60 articles in journals, conference proceedings, and books.

Our team spoke with Andreas about the history of smart textile development in Europe, current research and EC funding initiatives, as well as future challenges and opportunities. We would like to express our gratitude to Andreas for sharing his expertise and wealth of information with the SmartX community and invite you to sit back and enjoy part 1 of this two-part interview.

To start off, could you briefly explain the evolution of the smart textile field since its inception in the late 1990s?

Smart textiles emerged from the combination of textile material with electronics and the collaboration between established electronics and textile engineering communities, leading to a totally new class of large-area, flexible, conformable and interactive systems, also called Smart Fabrics and Interactive Textile, SFIT or e-textile.

These activities, also benefiting from the eagerness of the textile industry to develop new value-added apparel products, led to significant results in wearable smart systems, integrated multifunctional smart textiles, body sensor networks and context-aware sensor systems for enabling several applications in healthcare, protection, leisure and lifestyle management, fashion, lighting, tracking & localisation, industrial and manufacturing, automotive, military etc.

The technological evolution could be summarised in three phases:

a) the sensor is attached to apparel,

b) the sensor is embedded in the garment, and

c) the garment is the sensor (currently this is the “next generation” smart textiles/wearables).

The first promising R&D prototypes incorporated mainly electrocardiogram and respiration monitoring by implementing strain fabric sensors and fabric electrodes. Further development led to garment-based applications capable of recording biomechanical variables and physiological signals to monitor risks for cardiovascular diseases such as sleep disorders, physical activity, and post events.

Later prototypes focused on the improvement of SFIT enabling technologies (e.g. textile and organic materials), core modules (e.g. system design, interfacing, connectivity, and multi-parametric sensing), and integration towards fully functionalized garments, e.g. integration of optical fiber-based sensors and biosensors for sampling sweat and measuring sodium levels, pH, conductivity and sweat rate in real time, energy harvesting (through body motion, thermal generation and solar cells), as well as long and short-range power transmission.

Current research and development focuses on fully comfortable, multifunctional, reliable, low-power consumption and cost-effective wearable systems – in particular on interfacing, packaging, conformability (with stretchable and flexible electronics), and robust interconnexion.

Over the period of 20 years, the field has evolved dramatically from a technology proof of concept and lab demonstrators to a new fashion/consumer experience and business paradigm, putting smart textiles and wearables at the heart of the data economy.

Smart textiles are now being used at a larger scale in many application areas: workplace safety, productivity and security, smart houses, healthcare or banking. They are also viewed as tools for new ways of human-to-human and human-to-machine interaction and connection.

Tell us a little about the history of EU support for smart textile research.

Smart textiles and flexible & wearable electronics are a growing sector, which includes a large variety of interdisciplinary technologies, processes, and applications. As such, it’s being strongly supported worldwide and in particular under the Information and Communication Technologies activities of the R&D framework programs (FP) of the European Union, starting from FP5 [1998-2002], and continuing with FP6, FP7 and the H2020 programme [2013-2020].

Credit: European Commission

As an example, we can highlight a group of ten projects supported by the ICT programme-Competitive Electronics Industry (alias Components & Systems) in FP7 [2007-2013], including height R&D, one CSA (Coordination and Support Action) and one pre-commercial procurement (combining R&D and CSA). The cluster involved 94 different organisations, incl. research centres, large industries, SMEs (Small and Medium-sized Enterprises), higher education organizations, public organizations, associations, etc. and an EC funding of 43.5M€.

Up until recently, the innovative technological projects supported used to focus mainly on devices, systems, and process development and improvement, e.g. electronics integration in textiles, stretchable and flexible foil substrates, roll-to-roll fabrication process, device integrating processes (e.g. pick-and-place techniques), and the electrical interconnection process (conductive circuit knitting, weaving, embroidery).

The projects have delivered substantial results, such as several advanced prototype demonstrators, spin-offs, patents, and a significant amount of peer-reviewed journal publications. At the same time, they showed current limitations and the underlying need for further support along the value chain – from development to manufacturing and innovation.

Present-day research and innovation projects are supported in H2020 under the electronics competitive industry programme line, with a total funding of 31M€, involving 66 European organisations. They address technology building blocks (e.g. wearable multiplexed biomedical electrodes, sensors and actuators to monitor physical and emotional wellbeing and energy supply for wearable electronics), multi-sensing integration (e.g. a patch for real-time detection of infectious diseases) and prototype validation, as well as manufacturability.

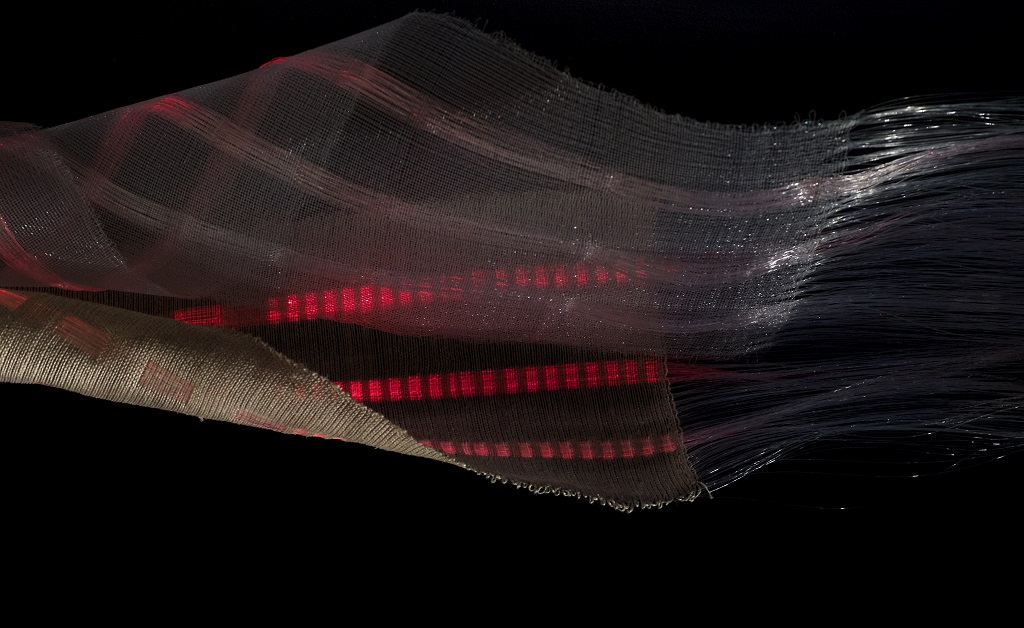

Image courtesy of Andreas Lymberis

The area has also been supported through other European Commission activities and parts of the R&D&I Framework programme. For example, in the period 2018-2020, the European Innovation Council Pilot, supporting deep tech SMEs to validate and scale up technology (TRL 5 to 9) with grant and equity funding, has been funding 64 Projects in Cloth-textile-Wearable areas with 100M€. Representative examples include: advanced synthetic biology in textile dyeing, Zinc-oxide antibacterial coating for textiles based on the “cavitation” phenomena, and advanced software allowing customers for the first time to freely shape their furniture individually.

The European Commission has also been providing financial support to SMEs and starts up for collaborative and innovative concepts/solutions/ideas for market uptake. The ELIIT Project, funded by the COSME Programme of the European Union for the Competitiveness of Enterprises and SMEs, supports European cooperation to promote the use of technology-ready solutions to improve productivity, value chain integration and resource efficiency, and to create new high added-value products and services in the Textile Clothing Leather and Footwear (TCLF) sector.

ELIIT has been supporting TCLF SMEs in implementing the excellent research results achieved in many technological areas by providers and owners of innovative and disruptive technologies: Key Enabling Technologies (KETs), digital tech, artificial intelligence, Internet of Things (IoT), etc.

In the new R&I Framework Programme, Horizon Europe [2021-2027], smart textiles will play a key role in several funding activities, targeting key European priorities such as green deal, digitisation, and manufacturing. This includes materials for the benefit of society and the environment, materials for the decarbonising industry, innovative materials for advanced nanoelectronic components and systems, and functional electronics for the green and circular economy.

In the Smart Wearables: Reflection and Orientation Paper, you talk about the need for Europe to lead the next tech disruption. Could you elaborate?

New generation wearables will be flexible, fashionable, and invisible. They will go beyond wrist worn devices or “simple” integration in clothes. They will embed advanced features: energy harvesting, efficient power management, and very low-power high-performance computing.

Moreover, coupled with advances in mobile communication, software and internet technologies, tools and open architectures (e.g., IoT, edge computing, data analytics and artificial intelligence), wearables are able to harness data from individuals or their ambient environment to provide actionable feedback to anyone, anytime, and anywhere.

The disruption will operate at the level of individuals and the way they interact, work and live, but also at the societal, professional, and business levels.

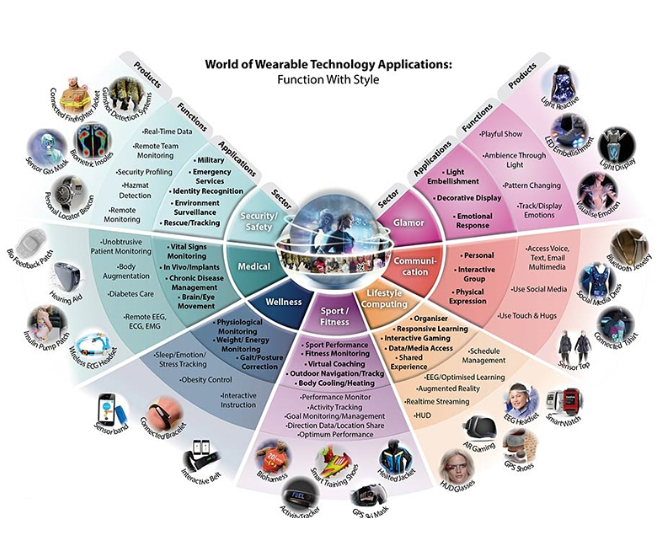

Application areas and product categories for wearables. Credit: Beecahm Research

For Europe, this also means integrating wearables and small textiles in a broader research and development context e.g. in combination with flexible and printed electronics and in the global digital strategy and action plan, including GDPR (General Data Protection Regulation) and e-Privacy rules, free data flows beyond the EU, cybersecurity, citizens awareness and education, and with a stronger focus on the use of wearables in an industrial environment.

Along these lines, smart textiles and wearables will have to comply with the new rules implied by the digital transformation and contribute to the discussion regarding the long-term ethical, environmental, political, social/cultural, economic, and sustainability aspects.

A workshop organised by the EC in December 2018 to consult with main stakeholders in smart wearables, flexible, and printed electronics has put forward the main needs of these sectors and made recommendations to accelerate developments and innovation and strengthen European leadership. Safeguarding of strategic autonomy and guaranteed resilience of flexible and printed electronics value chains, as well as considering the full product life cycle, including recyclability and sustainability, are among the priorities for the community.

Other urgent needs relate to:

- an easy and cost-effective access to manufacturing foundries in Europe for prototyping and low/mid-volume production;

- the capacity to build strong investment cases for public funding, venture and other capital investments;

- design and prototyping activities at up to TRL 4/5 to trigger downstream developments and strategic coverage of key value chains;

- common approaches to IPR, licencing, certification, standardisation, and training.

The strategic response to these needs can be formulated along four main axes:

- Community building: e.g. a research and industrial roadmap, coordinated actions to stimulate investment, support industrial manufacturing, technology transfer, and market reach;

- Research and Development: Science & Technology challenges and a link to application areas. Focus on the roadmap priorities and cover development and validation in relevant environments (TRL5): manufacturing, device architecture, design and testing;

- Cost- effective access to technology and production facilities: e.g. technology trials, prototyping, small series, and routes for volume production;

- Manufacturing base building: support of manufacturing capability for scaling-up production in Europe. e.g. equipment, process integration, and reliability.

Market analysts believe next generation wearables will provide significant opportunities to well-established textile companies for creating value, as this may render the current generation of wearable gadgets by Apple or Samsung and all such providers obsolete. Europe has a good starting basis thanks to a strong technical textiles industry.

Disclaimer: These views are from the author and do not necessarily reflect the ones from the EC. (February 25, 2021)

Read the second part of our interview, where Andreas discusses the future of European smart textiles, in particular the current challenges and opportunities.